|

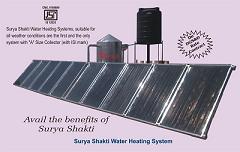

Surya Shakti Solar Water Heating System

Utility & Applications of Surya Shakti Solar Water Heating Systems Surya Shakti Solar Water Heating Systems are useful to meet the requirement of hot water of Defence, Industries, Hotels, Hospitals, Hostels, Mess, Canteens, Religious and Charitable Institutes, Educational Institutes, Residence etc., for bathing, washing, cleaning, cooking, process heating, Boiler feed water, Leather tanning, Food processing, Space heating, H.D. Oil heating, Component washing, Dyeing, Painting, Ice Melting at high altitude areas, etc. Available Sizes of Surya Shakti Solar Water Heating Systems Available in different sizes of 100 litres per day (LPD) at 60º C to 1,00,000 litres per day at 85º C for plains, Deserts, High Altitude areas, with or without Heat Exchangers & Electrical Back-up with Epoxy coated M.S. or stainless steel hot water storage tank. Available in thermosyphen as well as Forced Flow mode with different designs & configurations. Surya Shakti SWHS with Double Loop / Heat Exchanger Special systems with copper coil heat exchanger i.e. double loop is developed and provided to prevent scale formation or freezing of water at the locations where water is salty or ambient temperature goes Sub-zero. Components Of Surya Shakti Solar Water Heating Systems

Working of Surya Shakti Thermosyphen System Basic Surya Shakti Solar Water

Heating System works on the Thermosyphen principal. The system is fed by cold

water supply either under gravity flow, from Over-head Cold Water Tank

(generally at 8 ft height to be provided by user, unless or otherwise specified)

or through pump. In thermosyphen systems storage tank (Hot water) is kept above

Solar Flat Plate Collectors. To start with cold water is filled in Storage Tank

(HW). In the morning as the sun rises the Collectors gets heated up and water

inside the riser tubes rises by natural convection on top of the storage tank

and colder water from bottom of the storage tank flows in Collector under

gravity. Thus the natural circulation is automatically established whenever

there is sufficient sun-shine and automatically stops during insufficient

insolation when the upward buoyancy force is unable to overcome fluid friction

losses inside plumbing. Once Storage tank reaches at sufficiently higher temp,

you can use the hot water from utility side by operating taps as and when

required. The cold water entry to the system will be controlled automatically.

Benefits of Surya Shakti Solar Water Heating Systems

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||